CNC Processing

Shangli’s custom CNC services are the solution for companies, engineers, product developers and designers who need custom aluminum extrusions. From simple designs to complex designs with tight tolerances, our ISO 9001 certified CNC machine shop ensures excellence. Our salt spray testing certification guarantees product quality, and our rapid CNC machining capabilities guarantee the production of high-quality custom machined parts in 1 day.

Send your design files to our email address sales13@fsshangli.com, and we will give you the pricing, delivery time and DFM details of the CNC components immediately upon receipt. We specialize in CNC machining of aluminum alloys, providing adaptable production and shipping solutions to meet your product development needs.

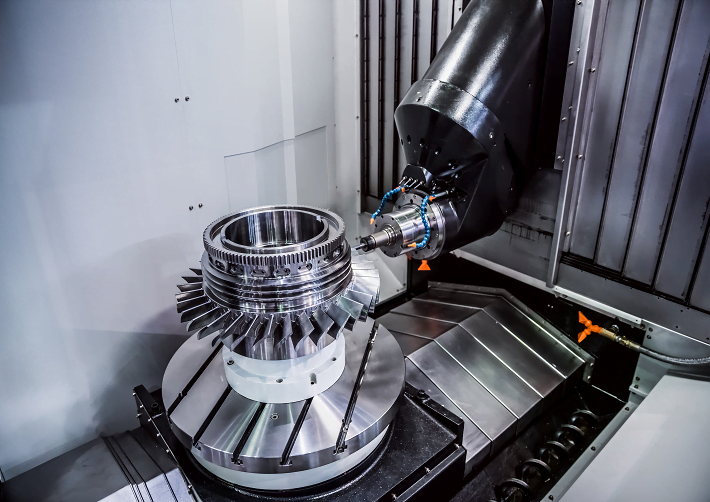

Custom CNC Milling Services

CNC milling performs multi-axis milling operations, including 3, 4, and 5-axis machining processes. Offer precision and allow for the creation of detailed and specific geometries from metal or plastic blocks.

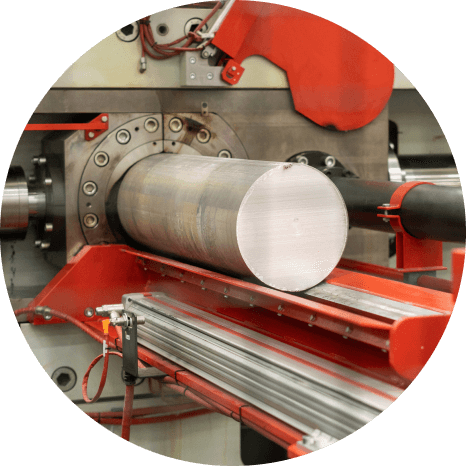

Custom CNC Turning Services

CNC turning uses CNC lathes and turning centers to shape metal rob stock, focusing primarily on cylindrical parts. Ensure components achieve consistent dimensions and smooth finishes.

Quality

Profiles guaranteed by our quality in Aluminum

Our quality laboratory provides the verification of parameters of all the products that go through our extrusion processes.

When concluding with an aluminum profile, a piece is extracted and we capture a photograph verifying in our database if the material has the characteristics that the client requires.

This quality control is revised in our state-of-the-art and high-tech system Romidot, which produces dimensional verification results in real-time. This allows for greater efficiency during the production of profiles, which translates into cost savings.

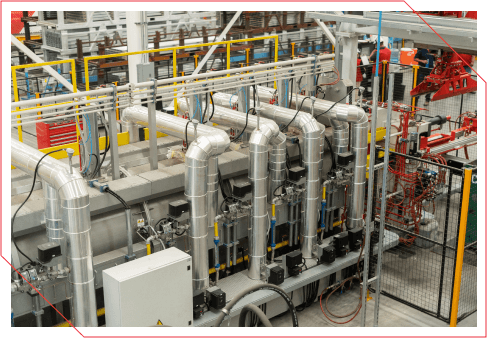

100% automated presses

Achieved with a minimum pressure of 40 tons per square inch of the surface of the die or mold pre-heated to 530°C, shaping the product to the requirements that the client requested. An optimally extruded profile requires three essential elements:

Extrusion is the main process at ShangLi Aluminum company. We exert pressure on the aluminum ingot towards a profile product, depending on the size and clamping force used, it will result in the flexibility to change the shape or appearance of the required profile.

Process

Without limits and flexible to create any profile you need

At ShangLi Aluminum, we offer you comprehensive solutions, being professionals in each project we work on. With a process where we adapt to your idea and generate the solutions that your product requires.

- We receive a physical sample, prototype or drawing of the profile that the client requires

- Based on the client’s sample, we carry out a feasibility analysis, reviewing commercial tolerances and the specific requirements for the product

- We make the project quotation for approval by the client

- At the time of confirmation, we create the dies according to the conditions stipulated between the client and ourselves

- The mold or die for the product is generated, as well as the operating instructions for the internal equipment

- Before delivering a sample to the client, we perform quality-control tests and verify functional conditions, requested measurements, and durability tests.

- Finally, the customer approves the test profile, and we start with the mass production of aluminum profiles.

Extrusion

- We start by integrating the three essential elements: press, mold, and ingot

- The ingot is pre-heated so that it reaches its molten state with the correct temperature, entering the appropriate extrusion press, generates the established pressure and pushes through the die, flowing at 530°C, becoming a soft and manageable material

- Once the aluminum profile material is cold, we proceed to the tempering process, stretching it and eliminating any deviation caused by cooling.

- We cut to size according to customer requirements.

Our aluminum factory service makes it possible to translate your idea into an aluminum profile according to your requirements, contributing our experience with the process and machining suitable for the product.